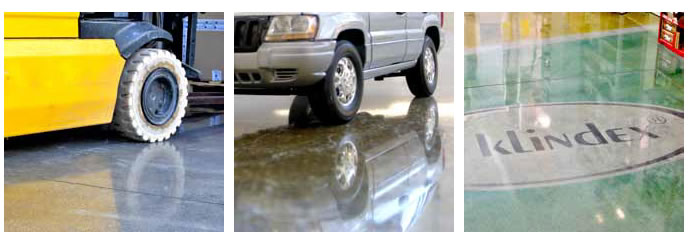

Thanks to the continuous research of new technologies for surface treatments, the KLINDEX Team has developed a new technique called SUPER CONCRETE that allows you to transform any old, ugly, stained or dusty concrete floor in a perfectly smooth surface, extremely resistant, shiny, incredibly beautiful, easy to keep clean and free of dust. Applying the SUPER CONCRETE technique on a new floor it is possible to obtain unimaginable results and comparable for aesthetics and resistance to a marble or a terrazzo floor. It is also possible to create designs and logos allowing your imagination to realize priceless artworks.

Superconcrete System

SuperConcrete is a polishing system for concrete developed by Klindex which turns every type of cement into a smooth, highly resistant and incredible beautiful glossy surface. With the SuperConcrete system even an old, stained and worn floor can be polished to make it look like new, extremely resistant, repellent to dirt, and easy to clean. With very few steps you will be able to polish, make waterproof, create logos, getting a nice surface like marble and strong as concrete. The SuperConcrete system offers different procedures to achieve different finishes: SUPERCONCRETE PREMIUM, SUPERCONCRETE FAST and SUPERCONCRETE TERRAZZO EFFECT.

BENEFITS

Easy to clean since the surface has become smooth and not rough anymore.

• There is no more dust since the dusty outward part of the floor has been removed.

• Resistant to traffic. Particularly suitable for forklift truck traffic that will not leave black tyre marks on the floor and will always have an excellent grip.

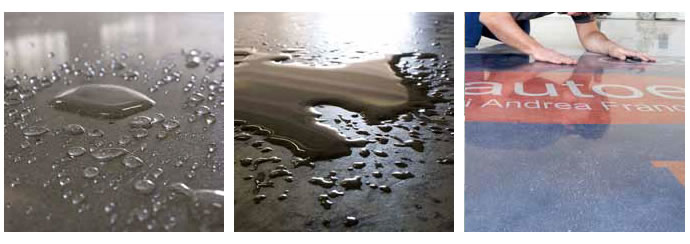

• Resistant to external agents since it is consolidated and waterproofed.

• It does not “scratch”. No unsightly streaks appear like on the floors covered with resins or paints. The surface is smooth and it is not covered by waxes, resins or filming products which can get scratched.

• Hygienic. The smooth surface, hardened and polished, does not absorb and so it is easier to remove germs and bacteria.

• Economical. To transform an old floor in an aesthetically beautiful new floor, it’s cheaper than any other solution. Also a polished floor compared to a rough cement floor allows considerable savings on maintenance costs, since the operating machines find less resistance and so less wear of the brushes, discs, wheels, mop, etc.

• Dyeable. Is it possible to add an artistic touch by coloring with impregnation colors called BETON COLOR DYE. The BETON COLOR DYE unlike paints or resins systems “do not cover the surface”, do not create a film but they go in depth reacting with the “cement salts”. So they do not scratch or peel like the paints and do not come off or don’t make bubbles like resins.

• Ecological. The floor is sanded and polished without application of resins, paints or other products potentially harmful and carcinogenic. There will not be over time migrate odours and volatilization in the air of microparticles that may cause allergies or health hazardous.

The advantages:

• Dust proof. • Durable surface. • Aesthetically pleasing. • Resistant to heavy traffic and forklifts. • Easy to clean. • Resistant to external agents. • Highly hygienic environment in the workplace. • Possibility to colour.

The technique in a few words:

• Concrete polishing • Elimination of height variances. Consolidation of concrete with a special hardener. • This process causes a chemical reaction resulting in the hardening of the concrete. • Polishing to obtain a high finish, shine and brilliance of the floor when cleaning, you can perform cleanup operations with a reduced consumption of chemical products.

Applications:

• Retail shops. • Logistics centres. • Garage. • Commercial areas and offices. • Production areas. • A modern environment. • Warehouses. • Parking. • Offices. • Airports. • Schools. • Showroom. • Galleries.• Museums. • Discos. • Pub.